Polystyrene recycling is one challenge on which progress has been made, but there is still a long way to go before cheap, efficient recycling methods are found.

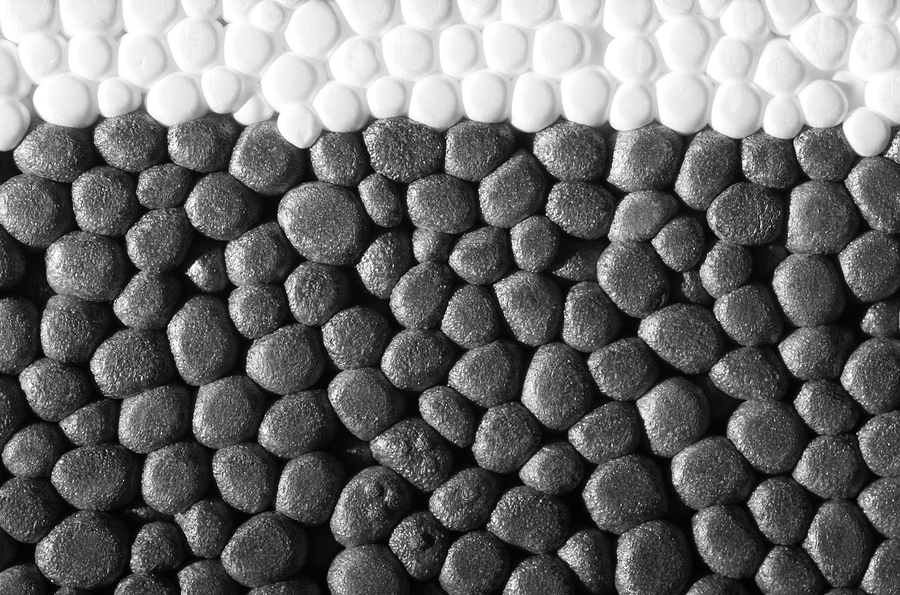

The white, fluffy material most of us think of when we hear ‘polystyrene’ is actually made from the same plastic as CD cases, but air is mixed in during the production process to make it much bulkier and more lightweight.

Dow Chemical Company invented the process in the 1940s – and own the rights to the trade name Styrofoam, which many people use when referring to polystyrene in conversation.

More recently, expanded polystyrene or EPS has become the commonplace term for the material, and there are slight variations available in terms of the exact production method, density and even the colour of the finished product.

One thing all of these materials have in common, unfortunately, is that there is currently no cost-effective way to 100% recycle them into new materials.

That might sound bad, but it’s true of a lot of the materials we use on a daily basis, from takeaway coffee cups (both polystyrene and insulated paper versions) to many plastic films, and even paper can only be recycled a handful of times before the fibres become too damaged to be used again.

With polystyrene, one of the solutions is not to recycle it, but simply to reuse it, and this is especially true in the case of products like polystyrene packing chips, which can be collected without being damaged and directly reused without needing any special kind of reprocessing.

As with all materials, reuse is more efficient than recycling, especially if there is no need for the material to be cleaned or processed to any great extent.

Even rigid polystyrene can be broken down into smaller pieces for use as loose packaging material, and there’s really no reason not to do this over and over again while the pieces are still clean and in usable condition.

Eventually they may become dirty or crushed, and this is when it becomes time to dispose of polystyrene once and for all.

It can be incinerated in efficient burners – although should not be burned on a normal fire as it may produce dangerous fumes under normal combustion conditions.

Used polystyrene may also be melted and compacted to turn it into plastics suitable for making other containers and products, or for use in insulation.

Ongoing research is finding new ways to deal with plastic waste – including bacteria that may be capable of digesting plastic as a source of food – and one day we may be able to use these as part of a more efficient closed-loop recycling process.

In the meantime, if you expect to produce large quantities of polystyrene waste, make sure you have a skip suitable for bulky, lightweight waste in the right amounts, from a skip hire provider who you know you can trust to dispose of your polystyrene – and all of your general waste, for that matter – in the most cost-effective and environmentally friendly ways that are currently available.